Let’s shed light on an innovation that could reshape the way airports manage their power infrastructure and help us achieve a more sustainable aviation industry.

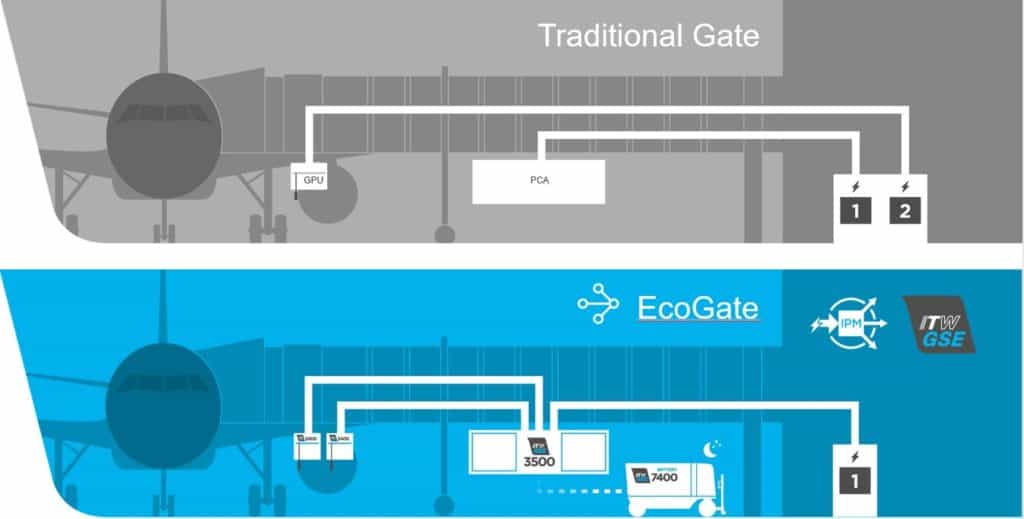

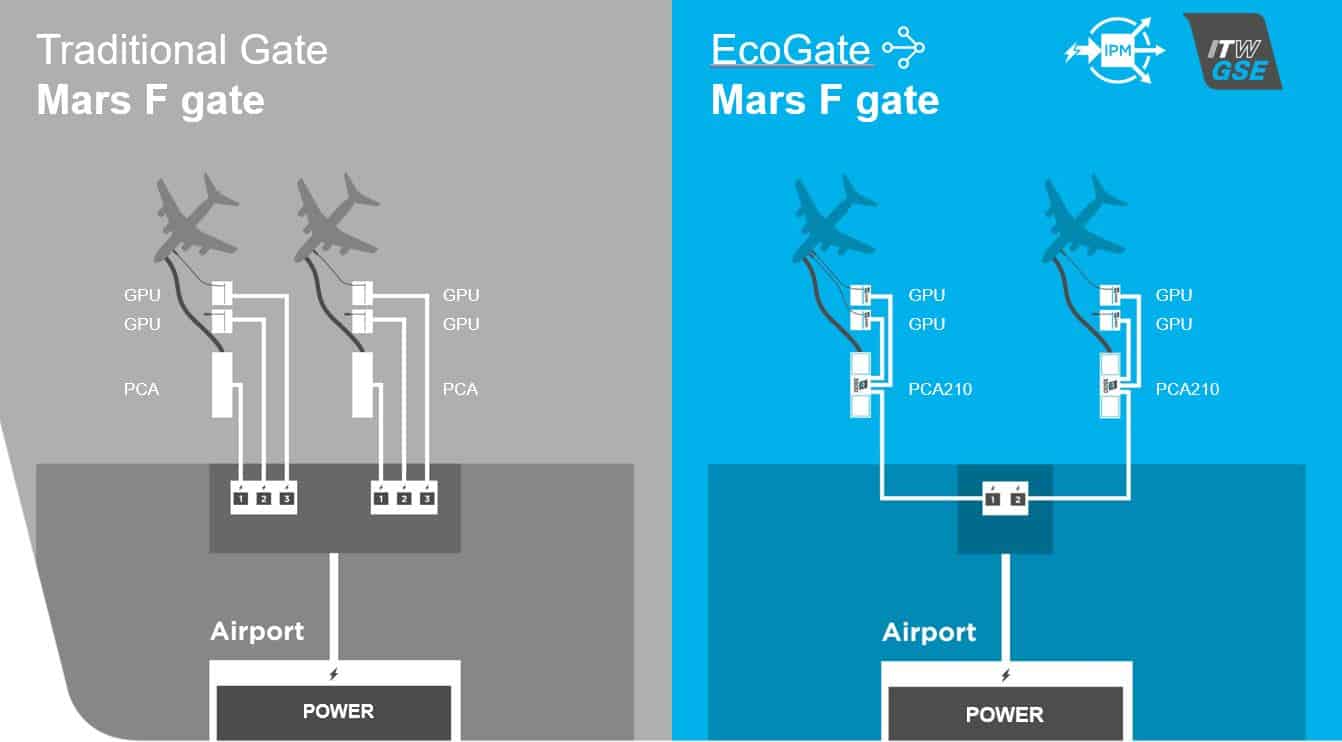

For years, airports have struggled with a significant challenge: how to efficiently power the vast array of equipment required to service aircraft while minimizing costs and environmental impact. Traditional gate auxiliary equipment has operated as individual units, often straining power capacity and resulting in inefficiencies.

Enter EcoGate – an innovative solution that has the potential to revolutionize the way airports think about their power infrastructure.

For decades, ITW GSE has been a pioneer in the Ground Support Equipment (GSE) market. From manufacturing the first PCA unit in the 1940s to introducing solid state GPUs in the 1980s and battery driven eGPUs in 2017, ITW GSE has consistently pushed the boundaries of innovation. And now, with EcoGate, we are once again pushing the boundaries of efficient gate economy.

EcoGate represents an ‘all in one’ solution that holds the promise of electrifying airport gates with minimal infrastructure cost. In an industry that is continuously striving to achieve carbon neutrality by 2050, ITW GSE has stepped up to the challenge by delivering EcoGate, which empowers airports to utilize their already installed gate power in a smarter, more efficient and sustainable way.

Intelligent Power Management

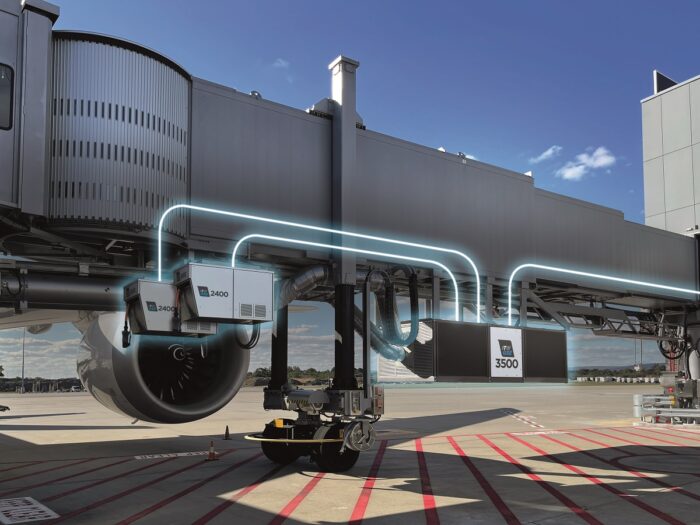

What differentiates EcoGate is its capacity to transform ground support equipment into a seamless and interconnected system. Hosted in the ITW GSE 3500 PCA, Intelligent Power Management is the brains of EcoGate, intelligently distributing power where and when it’s needed. This can result in up to 50% surplus power and, astonishingly, up to 100% when the system is not in operation during off-peak periods.

Additionally, by minimizing air loss from the PCA hose to the aircraft, the new 3500 Air Coil and new SuperHoses let EcoGate enhance not only PCA efficiency but the entire system, leading to a reduction in power consumption and a significant contribution to sustainability goals. This makes EcoGate the perfect solution not only for upgrade and expansion projects, where increasing power capacity is often challenging due to costs and complexity, but also for new airport developments.

Redefining aviation sustainability

The beauty of EcoGate lies in its flexibility. It allows airports to retrofit existing gate infrastructures at minimal cost, making it an economically smart choice. Instead of investing in costly infrastructure upgrades, airports can leverage their existing ITW GSE units and add EcoGate-enabled components as needed.

As the aviation industry looks toward a more sustainable and efficient future, EcoGate’s intelligent approach to power management could not have come at a better time. Airports can now make the most of their existing power infrastructure, enhancing efficiency, reducing costs, and contributing to a better work environment for the airport operators and for a greener environment in general.

EcoGate has already caught the attention of key players in the industry with the European market well on the way towards ramp electrification and the US market undergoing substantial modernization. Also, in Asia there is an increase in new airport developments showing increased demand for more environmentally friendly solutions, particularly in countries like Thailand, Hongkong, Philippines and Vietnam. EcoGate’s adaptability positions it as a solution ready for worldwide adoption.

EcoGate is not just a technological advancement; it’s a step toward a more sustainable aviation industry. By making the most of existing infrastructure, utilizing excess power from the grid, and improving efficiency, it aligns with the industry’s ambitions to go green while optimizing costs. It’s a win-win with perfect timing.

Below you see examples of EcoGate versus a traditional gate not using EcoGate: